For gym owners, wellness directors, and facility managers, the decision to install a cold plunge is no longer about if, but how. Market demand for cold water immersion (CWI) is proven. The real question is economic: does a commercial ice bath machine justify its total cost of ownership?

Is the upfront capital expenditure (CapEx) reasonable? How does long-term operating expense (OpEx) compare with residential chillers or the traditional ice-based approach?

Written from the perspective of an industrial-grade refrigeration manufacturer serving international B2B clients, this guide provides a transparent breakdown of commercial ice bath machine cost, helping buyers evaluate long-term value rather than short-term price.

1. Initial Investment: Understanding the Gap Between Price and Value

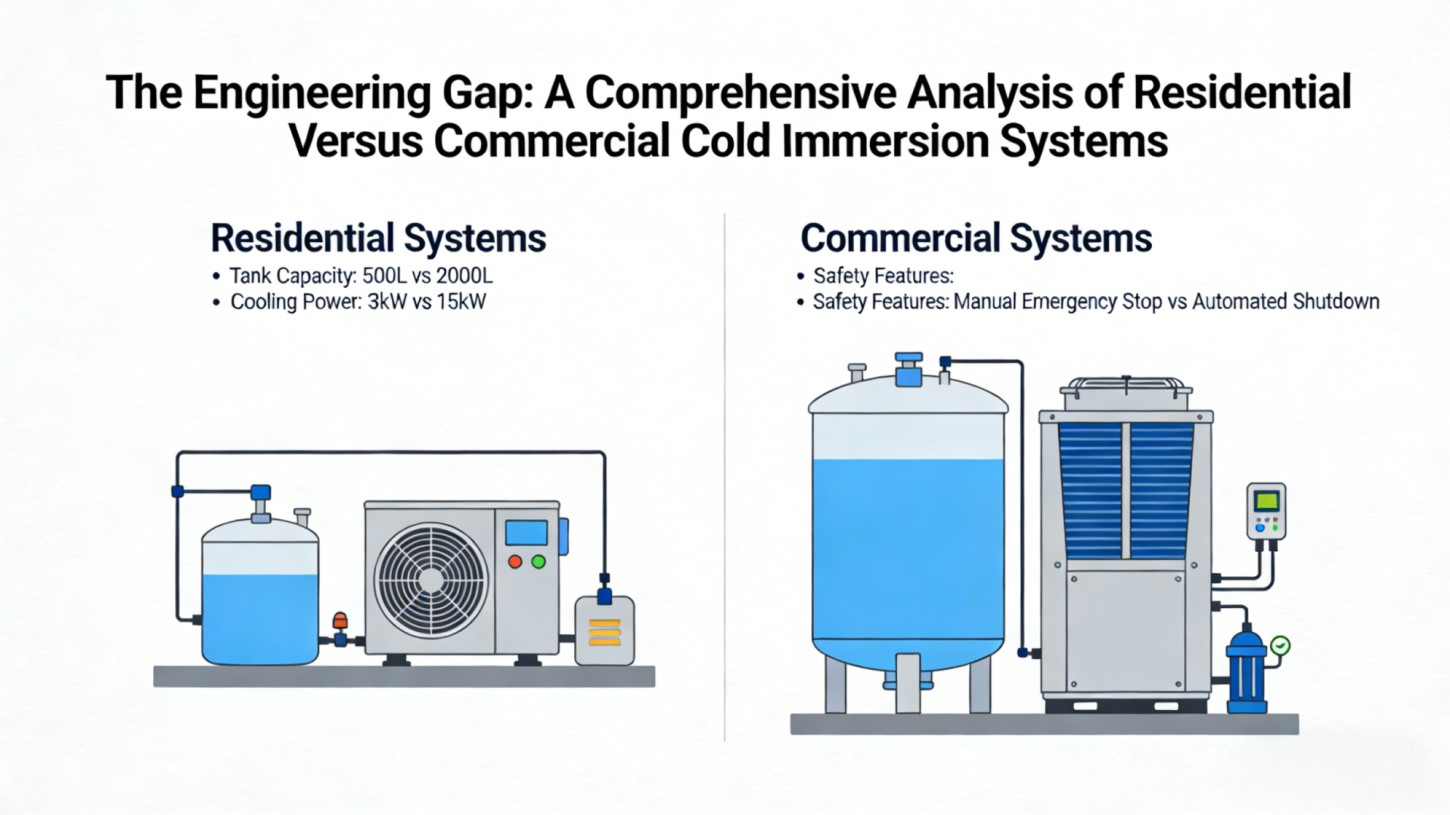

When evaluating cold plunge systems, it is critical to distinguish between residential-grade chillers and true commercial refrigeration equipment. The sticker price alone does not reflect operational durability.

Residential vs. Commercial Hardware

Residential or entry-level units (typically USD $800–$2,500) often rely on rotary compressors and light-duty heat exchangers. These systems are designed for minimal daily use and struggle under continuous commercial heat loads, leading to excessive noise, long recovery times, and early failure.

Commercial-grade systems (approximately USD $3,000–$10,000+) utilize scroll compressors and titanium heat exchangers. These components are engineered for continuous operation, rapid thermal recovery, and long-term exposure to chemically treated water.

The price difference is driven primarily by compressor technology. Scroll compressors—standard in commercial HVAC—offer superior efficiency, reduced vibration, and significantly longer service life under sustained load.

2. Infrastructure and Installation Costs

Beyond equipment pricing, facilities must account for installation requirements.

Electrical supply: Commercial systems typically require dedicated circuits (20A or higher) to handle sustained power draw.

Ventilation: Air-cooled chillers reject heat into the surrounding space. Adequate clearance and airflow are essential to prevent overheating and performance degradation.

Proper site planning ensures efficiency and prevents avoidable operating costs.

3. Operating Costs (OpEx): Ice vs. Energy Efficiency

A common misconception is that manually adding ice is a low-cost alternative.

The Hidden Cost of Ice

In a busy commercial facility, maintaining stable water temperature with ice alone can require approximately 15–25 kg of ice per day. At conservative pricing, this can exceed USD $6,000 annually—excluding labor costs and hygiene risks.

Commercial Chiller Efficiency

Modern commercial systems using R32 refrigerant and optimized heat exchange typically incur electricity costs of approximately USD $500–$800 per year, depending on usage patterns and local energy rates.

In most commercial scenarios, the break-even point between ice-based operation and a professional chiller is reached within 12 months.

4. Maintenance Costs: Protecting the Asset

Commercial ice baths experience high bather loads and require proactive maintenance.

Filtration: High-capacity pleated filters must be cleaned regularly and replaced as needed to maintain flow rates.

Sanitation: Integrated ozone systems significantly reduce chemical consumption while improving water clarity.

Preventive care: Routine condenser cleaning ensures airflow and protects compressor longevity.

These measures preserve performance and reduce unexpected downtime.

5. ROI Considerations: Throughput Drives Revenue

Revenue potential is dictated by temperature recovery speed.

Residential systems may support fewer than 10 users per day due to slow recovery.

Commercial systems typically recover temperature within 10–15 minutes, enabling 30–40+ sessions daily.

At standard per-session pricing, the revenue difference can be several hundred dollars per day—far outweighing marginal operating costs.

6. Hidden Costs and Common Purchasing Mistakes

Commercial buyers should avoid:

Uncertified equipment: Lack of UL or ETL certification may void insurance coverage.

Copper heat exchangers: Susceptible to corrosion in treated water environments.

Undersized systems: Units operating at constant maximum load consume more power and fail prematurely.

Conclusion: A Strategic Investment Perspective

The true cost of a commercial ice bath machine is the balance of CapEx, OpEx, and revenue generation.

While professional systems require higher initial investment, facilities benefit from lower operating costs, higher throughput, and long-term reliability. Manufacturers with commercial refrigeration expertise—such as Quanguan—design systems specifically for these operational realities.

For B2B operators, the most economical solution is the one that remains operational, efficient, and profitable over time.